As many of you know, I own my fair share of multitools. Okay, not as many as Def...but then again, Leatherman only has about 6 more tools in their warehouse than Def has in his house.

One of my favorite stand buys is the Gerber Multitool 600 series. This is the one that the pliers head is recessed in the tool and can be flicked out into a locking position with the flick of your wrist. It's really a cool design, and the "flickable" pliers are very easy to engage one handed, which has saved my bacon more than a few times.

See Gerber's page about it here:<a href="

http://www.gerbergear.com/product.php?model=7540G" target="_blank">

http://www.gerbergear.com/product.php?model=7540G[/url]

(okay, this is the newer version of the MP600 that has come out since the Diesel...but you get the idear. It's basically the same set up, but they've fixed a few blades and added tungsten carbide cutter inserts at the wire cutters--a feature that carried over from their upper end multitools of past.)

Gerber has recently come out with a beefed up version of the 600 series, called the Diesel.; There are MANY upgrades to the tools and pliers head. For a good, overall review, see here:<a href="

http://multitool.org/content/view/85/72/%C2%A0" target="_blank">

http://multitool.org/content/view/85/72/[/url]

(Thanks J-Sews for the great review!!)

The one thing that Gerber did away with on the new and improved model was the saw coupler. This coupler allowed you to exchange the blades for whatever type of jigsaw blade that you could find that would fit. (more specifically, they had to have a hole in the tang for the retaining wire to fit into. You'll see what I mean in the pics.)

Well...it just so happens that the implements on the 600 series are directly compatible with the design of the Diesel. The tool orientation is a bit different between the two tools, but I was able to rearrange two implements and remove the lanyard loop--which in all honesty doesn't get used on my multitools-- and get the coupler from a 600 that I had to fit into the Diesel. Now I have a much more usable Diesel for the tasks that I need it for. It's amazing what the gain of one different variation of an implement will make.

Okay, here's the pics:

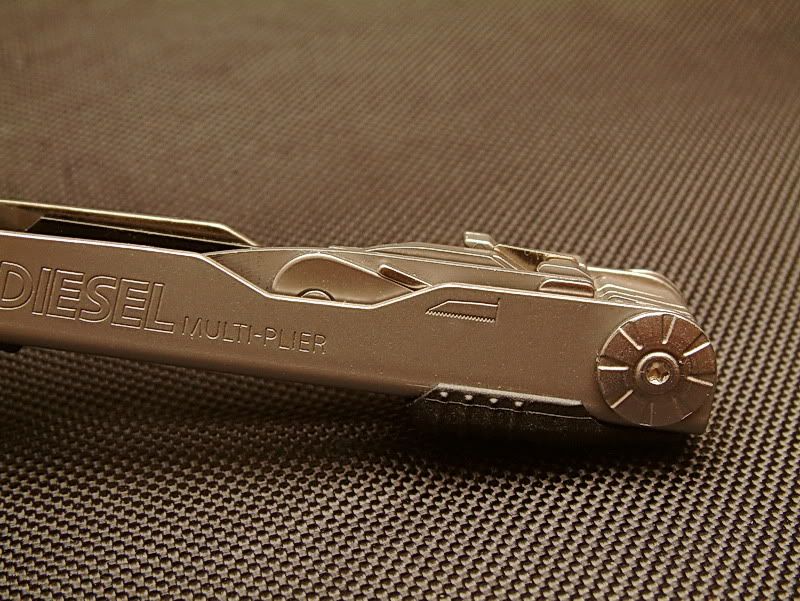

Here's the full length tool, after the change out.

The next few pictures are of the end of the tool that I modified. Sorry, but I didn't think to take a before picture. I'm sure i have one in my pics somewhere...I'll have to see if I can dig it up.

you can see here that the markings on the side of the tool that tell you what implement is behind that cutout are no longer correct, but I'm a "fart smeller" and can pretty much figure it out without the little drawings to assit me.

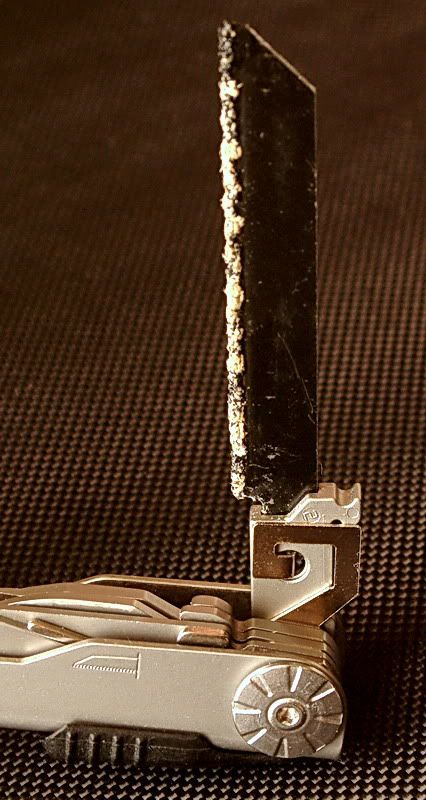

The white stuff on the saw blade is plastic from a toilet flush valve tube that I cut off yesterday. The blade that is in it now is the blade that comes standard with the 600's. It's called a RemGrit blade. It can cut pretty much anything, but it really excels at harder steel and porcelain. It doesn't have teeth, per se, rather a bunch of really abrasive powder and grit that abrades its way through whatever you are cutting. Downside is that it accumulates crud from whatever you cut. Usually I have a fine tooth hacksaw type blade in there, but didn't have one handy for the pics.

Okay, here's a few pics from the disassembly.

This one is of the pivot pin. If your familiar with the previous Gerber 600's, you'll notice that it's a bit different than the previous arrangements.

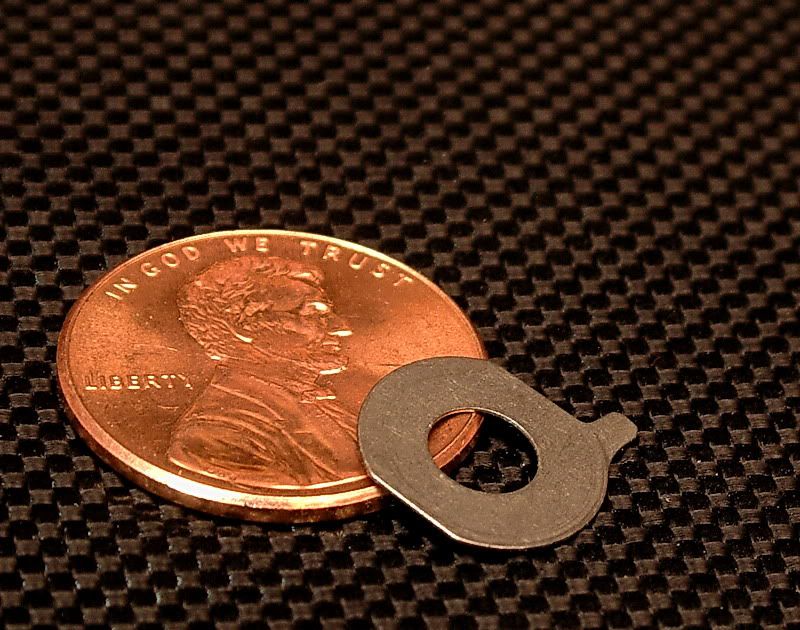

Here's a picture of the shims/spacers that they use to keep the tools separated and allow you to pull out one tool at a time. Putting these back in can, sometimes, be a real PITA...but the secret is to line it up with the tab forward and down. Then when you get all the implements and spacers you want in, pull the locking tab back and insert the pin. If you're very gentle it will all go back together very nicely and the spacers/shims will be locked into the locking tab so that they don't rotate.

This is spring that controls the locking tab. This causes the lock to re-engage when a tool is opened up. I removed mine and stretched them out just a bit so that the lock would engage more "positively." You don't HAVE to do this, but I like it when the lock "snaps" into place... just kind of a audible affirmation that the lock did engage. Of course, I'm weird like that too. Every ball point pen that I have has been disassembled and had the springs stretched slightly to make the clicking action more "positive." It's just a "quirk" that I have.

Here's the sliding pliers head lock and release button assembly with the button, spring, and retainer removed. The button has a little ledge that is held behind the oval grove on the side until it gets to the opening near the head. Once it gets to that opening, the button pops out and locks the head into place. When you want to retract the head, you push both buttons and push the head in, and this puts that little ledge beneath the oval groove again allowing the head assembly to retract back into the handles. Also note the little lumps of blue Loc-tite that was on the screws that held the button retainer on. All the screws on this tool have that Loc-Tite on them so they don't back out in use. When you're all done with your mods, it's really a good idea to put a little dab of NON-permanent Loc-tite on each screw for the same purpose...especially if you're hard on tools like I am.

Here's the remainder of the button assembly. These springs were stretched too so that the button popped out and locked more "positively." (It's a sickness I have, I tell ya!!)

This is a pic of the button and spring put back into the head assembly and pushed down the slide channel a bit to keep everythingn in place. The clamp keeps everything tight and keeps the spring loaded parts from shooting into hidden corners and crevices in my dining room.

Well fellas, that's pretty much it. All in all, it was a fairly easy changeout. Sure there's a few smallish pieces, but it's mostly about patience and perseverance. It all came out of there, so it must all go back in there.

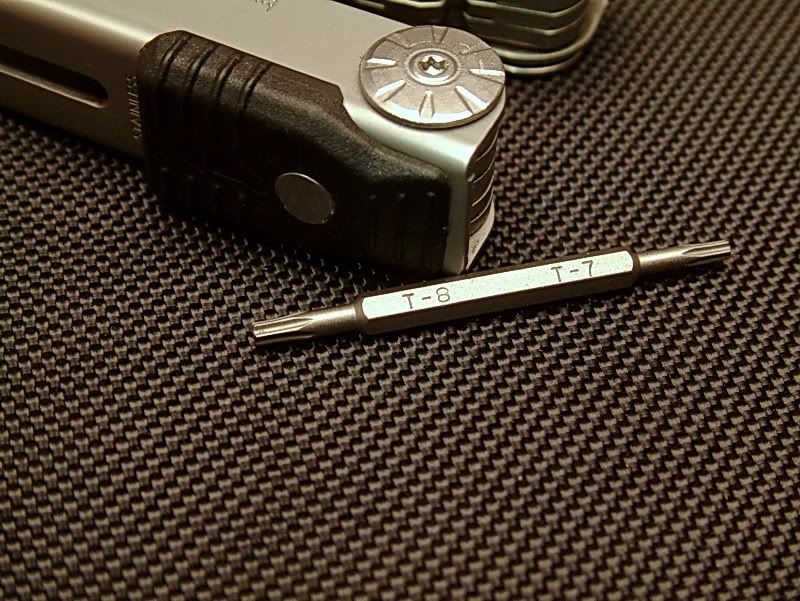

And, oh yah, these two tools make it much easier. A T8 torx bit/driver and a padded spring loaded clamp.

I have been carrying my newly modified tool a bit more now since I know that the saw bit I have in there now will work for the things I need to cut. And if it doesn't, I can at least now swap the blade out for one that will. Why Gerber opted to not put this patented saw coupler, which was a prime feature of their 600 series, into this "new and improved" version I'll never know. But with a little ingenuity and planning, I managed to re-engineer it to include it.

You may notice that there's some scuffing on the scissors and some of the other implements...that from sharpening and from use. The scissors are Gawd awful sharp now thanks to my Spyderco Sharpmaker.

Okay...Drewpy out. Thanks for looking.

(NOTE: The above is a re-post from a forum on which I'm a moderator. The guys there aren't quite as "in" to multitools as y'all here...so I apologize if I explained some of the more basic stuff a bit too much... and also, I'm known as Drewpy Dawg over there. O0)